-40%

150W 12V-24V Mini Beads Machine Miniature Lathe DIY Woodworking Lathe Grinding

$ 37.45

- Description

- Size Guide

Description

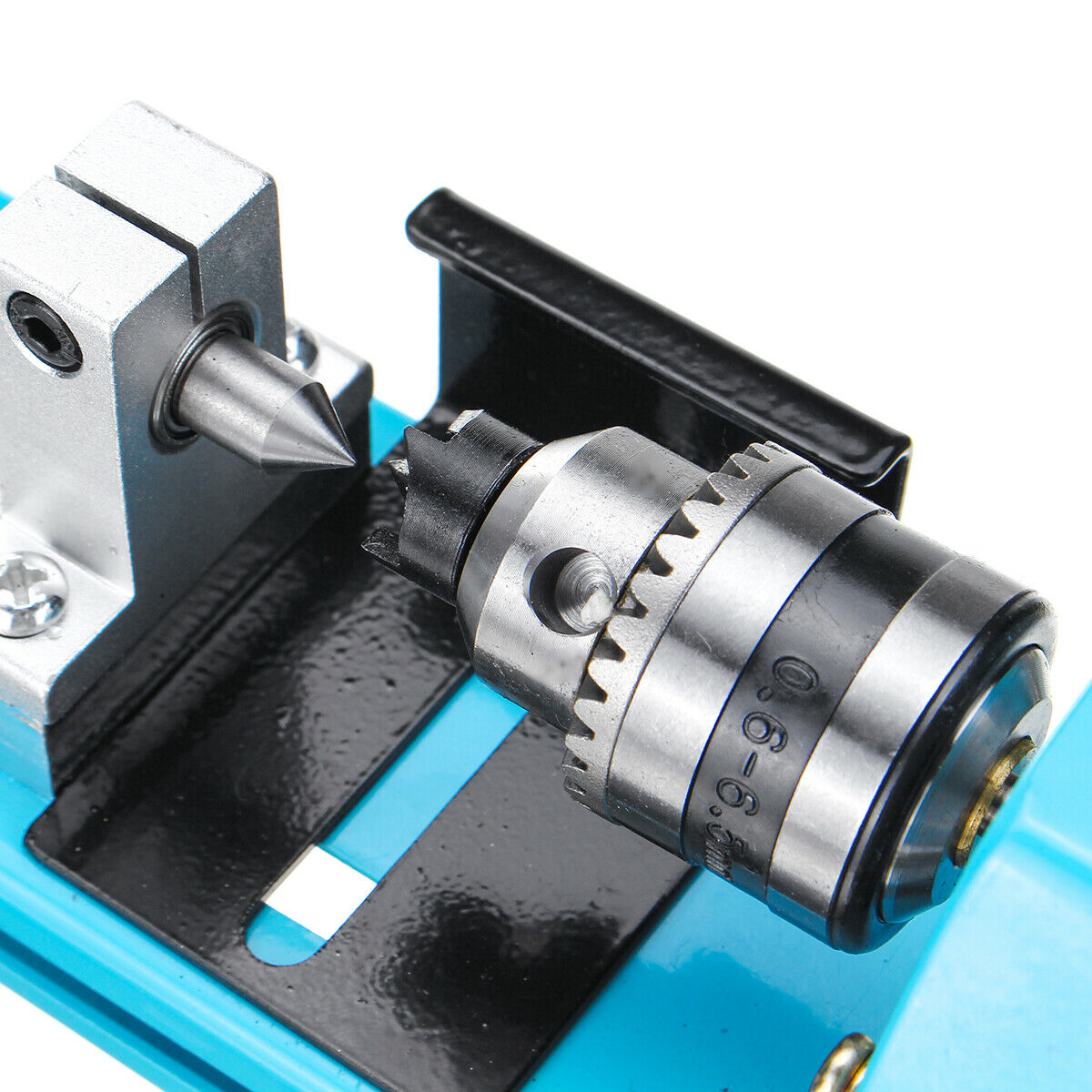

150W Mini Beads Machine Lathe Miniature Grinding Polishing Beads Woodworking DIY Drill Rotary Tool 12-24VDCFeatures:

1. Specially designed for the home DIY enthusiasts, small and portable size with strong power.

2. Stainless steel dustproof cover with super convective cooling hole.

3. The welding line is covered with a full heat shrinkable tube.

4. With 7 levels of power adapter enable you to adjust the rotating speed easily to meet different cutting speed.

5. High quality aluminum alloy base and pure steel structure drill chuck.

6. Super large torque ball bearing motor, maximum rotating speed up to 7000RPM providing ultra strong cutting power with low noise, you can use it at home.

Specifications:

Main material: Aluminum alloy

Color: Blue

Voltage Input: AC 230V 50/60Hz

Voltage Output: DC 12-24V

Rated power: 150W

Rated speed: 4000-7000RPM

Power: 7 level of adjustable speed

Max Processing length: 145mm / 5.7in

Max Processing diameter: 50mm / 2.0in

Chuck clamping range: 0.6-6.5mm / 0.02-0.26in

Swing diameter: max 50mm / 2.0in

Grip length: max 140mm / 5.51in

Matching saw blade diameter: max 50mm / 2.0in

Machine size: 345*60*80mm / 13.6* 2.36 * 3.15in

Package lncluded:

1 * Mini Lathe Beads Machine

1 * Speed Control Power Supply (12-24V)

1 * Fine copper carving kni-fe

1 * Thread fixed needle

3 * Beads fixed needle (1.5/2.0/2.5mm)

1 * Hex shank wrench

1 * Collet Wrench

1 * Metal saw table top

Tips:

1. If the user does not have lathe base experience, when using, uses should follow: low speed, slowly, cautiously and use other security operations.

2. The speed can be adjusted in 4000-7000RPM, speed of cutting wood should not exceed 5000, grinding can use higher speed.

3. Drill chuck axis, the axis of the wood, the tailstock center axis of the drill should be in a straight line, or need to adjust the nut.

4. If not a cylinder, the speed should be reduced.

5. Tailstock bearing without lock tight.

6. When using a kni-fe, locking the bottom of screw, location should be away from timber 1-1.5cm.

7. If you do not really understand the operation, it is best to consult a professional person.